Introduction

Ball-bearing is an indispensable mechanical component specially designed to serve a wide range of mechanical systems, ranging from everyday appliances like washing machines and electric fans to complex industrial machinery and high-performance aerospace systems. Plus, they are essential components in automotive applications, manufacturing equipment, conveyor systems, and precision instruments.

These small components are essential for smooth motion and reduce resistance between surfaces in contact to ensure optimal performance across diverse mechanical applications. In this article, we will discuss what is the purpose of using ball bearings in machines and how mechanical systems work across a wide range of applications.

Functionality of ball bearing

Ball bearings serve as an essential component in various machines and mechanical systems that offer the following functionality:

Reduces friction

Ball bearings minimize friction between moving parts by providing a smooth rotation surface. It ensures a smooth operation and prevents excessive wear on components.

Load distribution

Ball bearings distribute radial and axial loads evenly on surfaces by supporting the weight and forces exerted on rotating shafts or other mechanical elements. It helps to prevent premature failures and deformation of components under heavy loads.

Motion control

Smooth rotation in ball-bearing enables precise control of moving parts of machinery. Ball bearings become vital in applications that require accurate positioning, like robotics, precise machinery, and automotive systems.

Axial alignment

Ball-bearings guide in maintaining axial alignment between rotational components. It ensures they are correctly aligned, minimizing misalignment to induce stress and wear.

Shock absorption

In an application with more vibration and shock loads, ball bearings absorb and dissipate kinetic energy by reducing their impact on machinery and enhancing overall durability.

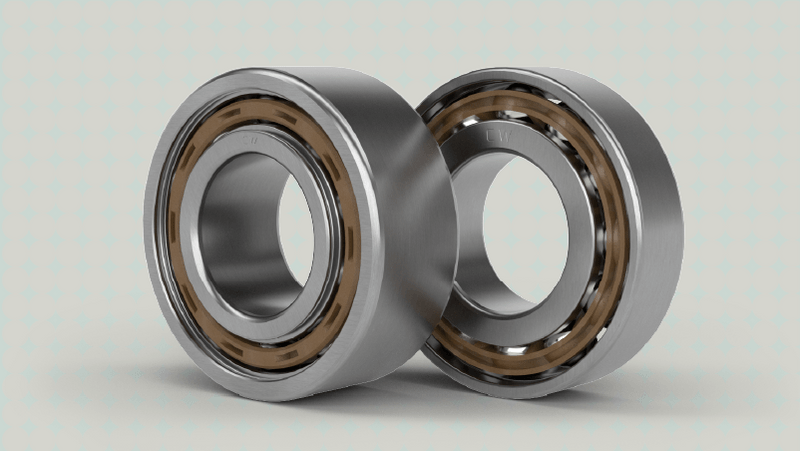

Components of ball-bearings

Ball bearings are operated by simple but effective mechanisms that consist of the following components:

Outer race

The outer race of ball-bearing is a ring-shaped structure that serves as a stationary outer bearing surface. It gives support and containment for other components.

Inner race

The inner race, or ring-shaped structure, rotates along with the machine's shaft or any other rotating components. It consists of balls and facilitates smooth rotation.

Balls

Spherical balls are usually made of steel or ceramic and are positioned between inner or outer races. These balls roll freely within the races, reducing friction and enabling smooth rotation.

Cage

In many ball-bearings, a cage or separator maintains spacing between the balls and prevents them from contacting each other. It ensures the load is even and minimizes frictional resistance.

Principle of operation

The operation of ball-bearing simply relies on the following principles:

Rolling contact

Ball-bearing operates on the principle of rolling contact, where spiral balls roll between inner and outer races just then sliding. It reduces friction and wear, which results in smoother operation and extended lifespan.

Point contact

The contact between balls and races occurs at minor points. It reduces the contact area and minimizes frictional resistance. Plus, the contact allows for efficient load distribution and facilitates smooth rotation.

Lubrication

Lubrication is necessary for the effective operation of ball-bearing. It reduces friction, dissipates heat and protects the application against corrosion by ensuring optimal performance and longevity of bearing.

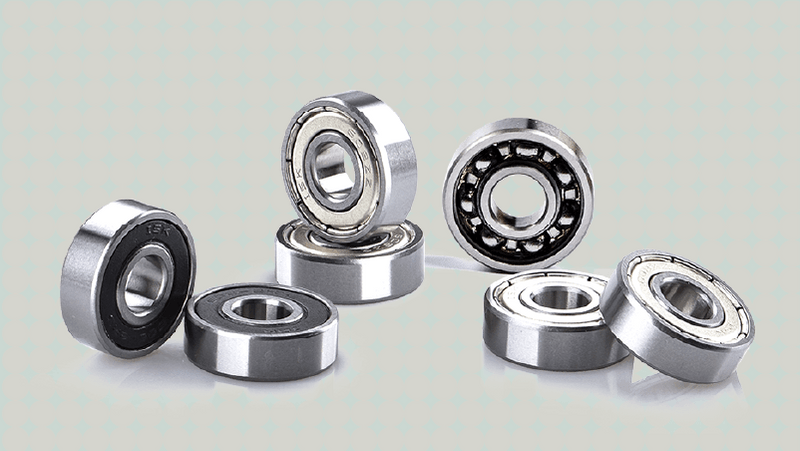

Different Types Of Ball Bearings & Applications

Ball bearings come in various configurations to suit different applications and operating conditions. Some of the most common types are:

Deep groove ball-bearings

Deep groove ball bearings are the most popular ball-bearing. They are featured by the deep raceway grooves that enable them to accommodate radial and axial loads in both directions. These bearings are used in applications such as electrical motors, pumps, and automotive components.

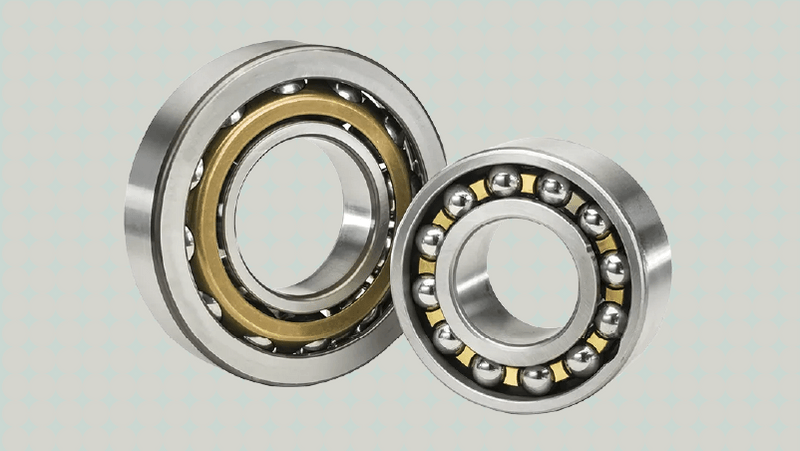

Angular contact ball bearings

The ball bearings are designed to accommodate angular contact between balls and raceways. They have higher load-carrying capacity that goes in one direction and are often used in pairs or sets. It supports thrust loads in addition to radial loads. Moreover, Angular contact ball bearings are used in machine tool spindles, automotive wheel hubs, and precision equipment.

Thrust ball-bearings

They are specifically designed to accommodate axial loads in one direction. Thrust ball-bearing contains a shaft washer, housing washer, and set of ball retainers. They are commonly used in aircraft engines' automotive transmissions, steering systems, and thrust reversers.

Self-aligning ball-bearing

Self-aligning ball bearing is designed to balance misalignment between shaft and housing due to deflection or mounting errors. They have two rows of balls and spherical outer rings that allow them to self-align and compensate for misalignment. Industries commonly use self-aligning ball bearings in conveyor systems, paper mills, and agricultural machinery applications.

Miniature ball-bearing

They are small-sized ball bearings with diameters ranging from a few millimeters to a few centimeters. Additionally, manufacturers commonly use them in precision instruments, electric motors, and small appliances with limited space.

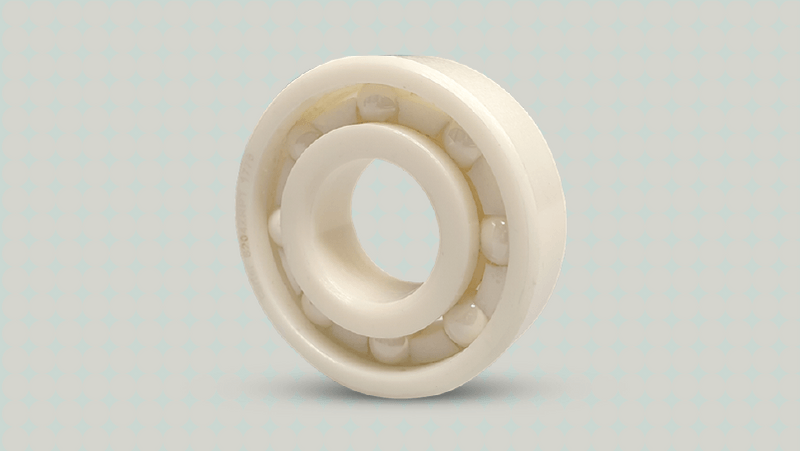

Ceramic ball-bearings

Ceramic ball bearings use ceramic balls instead of steel balls. They offer benefits like higher speed capacity, lower friction, corrosion resistance, and high-temperature resistance. In high-performance applications like racing cars, aerospace equipment, and medical devices, manufacturers often use them.

Hybrid ball-bearings

They are a combination of ceramic balls with steel races or vice versa. Plus, they balance ceramic balls' performance and steel races' cost-effectiveness. Manufacturers commonly use hybrid ball bearings in applications where high speed, low friction, and durability are critical.

It means manufacturers use them in machine tool spindles and electric vehicle transmissions.

Importance of Ball Bearings in Machines

Reducing friction

Friction is a natural force that resists the motion between two surfaces in contact. In machinery, friction may lead to energy losses, head generations, and premature wear of components

Ball bearings reduce friction by replacing sliding friction with rolling friction. The spherical balls within the bearings allow fluid motion between inner and outer races and minimize resistance and energy loss.

Ball bearings and friction reduction optimize the machinery's performance and efficiency. It leads to energy savings and improved operations.

Enhancing efficiency

When ball bearings reduce the fireball bearings, directly translates into enhanced efficiency in machinery.

With lower frictional resistance, less energy is required to overcome forces acting on moving parts. It results in smoother operation, reduces heat generation, and improves power transmissions throughout the system in applications like manufacturing and automotive systems, where precision accuracy increases efficiency by providing ball bearings to contribute to higher productivity and overall performance.

Increasing durability and longevity

Ball bearings play an essential role in enhancing the durability and longevity of machinery components. If the friction is reduced and loads are distributed evenly, the ball-bearing can prevent excessive wear and stress on critical parts like shafts, gears, and housings.

As wear and tear are reduced, the machinery's service life is extended by reducing the frequency of maintenance and repair activities.

Moreover, ball bearings are designed to handle high speed, heavy loads, and harsh operating conditions, enhancing their durability in demanding industrial environments.

Their capacity to withstand applications for prolonged periods makes indispensable components that ensure reliability and longevity in the machinery.

Advantages of Using Ball Bearings in machine

Efficiency Enhancement

Ball bearings are essential in increasing the efficiency of machinery and mechanical systems. It reduces friction in rolling motion and energy losses due to sliding friction in conventional bearing systems.

The reduction in friction changes into higher energy efficiency, as it requires less power to overcome resistance during operation.

As a result, machinery equipped with ball bearings operates smoothly and uses less energy, leading to cost savings and improved environmental sustainability.

Due to this, machinery can achieve higher speeds and handle heavier loads without affecting its performance.

Load Support

Ball bearings provide reliable support to both radial and axial loads. Its design allows the distribution of loads evenly across their surfaces by preventing localized stress concentrations that lead to premature wear or failure of machinery components.

The loading bearings capacity makes it suitable for various applications, from light-duty consumer products to heavy-duty industrial machinery. Ball-bearing excels in providing dependable load support under various operating conduit conditions, whether sorting the weight of rotating shafts into electrical motors or handling the thrust forces that are rated by automotive transmission.

Versatility

Ball bearings are highly versatile components that suit a diverse range of applications and industries.

Their designs, with a range of availability in various sizes and configurations, and compatibility with different materials and lubricants make them virtually suitable for any machinery or mechanical system.

Whether automotive, aerospace, industrial, or consumer electronic applications, they offer consistent performance and reliability across various environments and operating conditions.

Furthermore, due to advancements in ball bearings, they are optimized for specific requirements like high-speed operation, extreme temperature, or corrosive environments.

It ensures that ball bearings can meet the unique needs of each application, making them an indispensable component of modern engineering and manufacturing.

Application of ball bearing in various machines

Automotive industry

Ball bearings are essential for various components like engines, transmissions, and wheels in the automotive sector. In engines, they support rotating shafts and help reduce friction between moving parts; in transmission, they enable smooth gear shifting to facilitate rotational motion. In addition, wheel assemblies support vehicle weight and allow efficient rotation to contribute to fuel efficiency and driving comfort.

Industrial machinery

Ball bearings find applications in various industrial equipment, including pumps, conveyors, turbines, and manufacturing machinery. They are essential in maintaining smooth and reliable operation under heavy loads and high speed. Ball bearings optimize production processes, enhance productivity, and minimize downtime by reducing friction and minimizing wear.

Aerospace and aviation

The aerospace industry stands on two essential factors- precision and reliability. Ball bearings are used in aircraft engines, landing gear, control systems, and other components. They can withstand extreme temperatures and high-speed roads, making them indispensable for ensuring aircraft systems' smooth and efficient operation.

Upcoming changes in ball-bearing technology

Material

Ball-bearing manufacturing is compatible with material science and competes with technology. These bearings have superior durability, corrosion resistance, and temperature tolerance compared to steel bearings. On the contrary, ceramic bearings win for their lightweight construction and ability to withstand high-speed and extreme temperatures.

Design innovation

Modern ball bearings add innovative design features to enhance performance and reliability. Seals and shields are added to ball-bearing assemblies to protect against contamination and retain lubrication. Advanced sealing technologies like labyrinth and contact seals provide superior protection against dust, moisture, and other contaminants.

Conclusion

Ball bearings play a vital role in machinery by reducing friction, enhancing efficiency, and increasing durability. They can cache and facilitate smooth motion and distribute loads, making them flake a wide range of applications.

Machines can avoid increased energy consumption, decreased reliability, and shortened service life with ball bearings. Hence, the importance of ball bearings in machine performance and operational excellence cannot be overstated and it is only understood well by a top bearings & transmission manufacturing company, that guides you towards a reliable and purposeful ball-bearing in machines.

A right ball bearing manufacturer helps to reduce energy consumption, decreases reliability, and shortens service life by producing quality bearings that are prone to premature failure and increased friction.

Ready to Optimize Efficiency? Explore the Benefits of Ball Bearings in Your Machines Now!