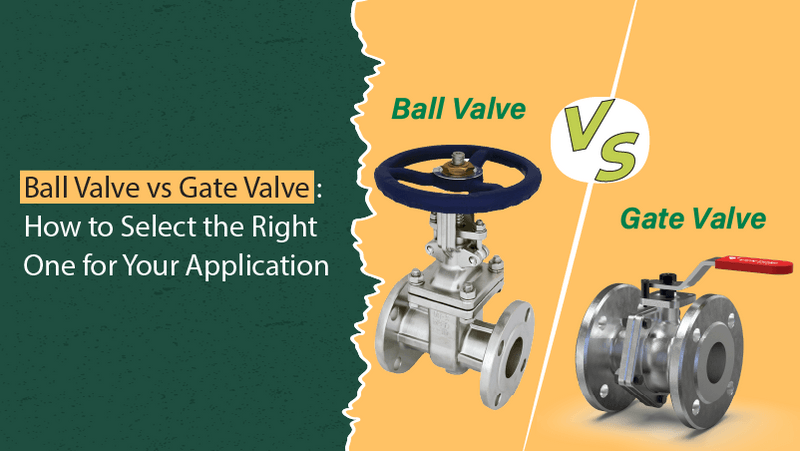

Are you looking for a valve that best suits your specific industrial application? Or do you need help with inefficiencies in your current valve systems? If yes, then worry not.

This guide will help you choose the right valve with confidence. As an industrialist, you cannot afford to experiment with different valves, such as ball or gate valves, to meet your requirements. It would be best to have a reliable, ready-to-use, and tested valve.

But how do you know which valve is suitable for you? Ball valve or gate valve?

Hence, this blog is here to help you compare ball and gate valves. There is no need for experimentation and error; simply read through and discover the valve that best suits your needs.

Let’s explore.

Understanding Ball Valve

Ball valve is one of the common valves that is used in a variety of industries and commercial uses. Hence to understand its capabilities let's discuss its definition, advantages and disadvantages, and application with detail in this section. Let’s start with its definition:

What is a Ball Valve?

A ball valve is an industrial valve used to control the flow of liquids or gasses. It has a spherical ball with a hole in the middle that rotates another way to allow or stop the flow of fluid or gasses.

When the hole in the ball is aligned with the pipe, fluid can pass through, and when it's turned perpendicular to the pipe, the flow is blocked. For example, in a manufacturing plant, a ball valve might be used to regulate the flow of water or chemicals in a pipeline.

Generally, there are four main types of valves :- Floating Ball Valves : The ball moves freely to seal when needed.

- Trunnion Mounted Ball Valves : The ball is fixed by bearings for handling high pressure.

- Full ball Ball Valves : A big ball allows maximum flow through.

- Different ports for versatile flow control. :

Advantages and Disadvantages of Ball Valves

Ball valves are crucial in various industries, including manufacturing, oil and gas, and hydropower. Their benefit is its ability to provide reliable fluid and gas flow, which ensures smooth operations. Apart from smooth operations, ball valves offer several advantages and disadvantages that include:

| Advantages | Disadvantages |

|---|---|

| Easy to open and close quickly. | Not suitable for throttling. |

| Provides a tight seal with minimal leakage. | Can be expensive compared to some other valve types. |

| Low maintenance requirements. | Can become stuck if not operated for long periods. |

| Durable and long-lasting in various environments. | Requires significant space for operation in larger sizes. |

| Minimal pressure drop when fully open. | - |

| Versatile for a wide range of applications. | - |

Applications Where Ball Valves Excel

Ball valve manufacturers design valves in a way that they excel in various industries. Here are some applications where ball valves are particularly effective:

Oil and Gas IndustryBall valves are extensively used in the oil and gas industry for upstream and downstream applications. What makes ball valves the ideal choice for the oil and gas industry is the ability to control the flow of oil and gas. Further ball valve exporter design tailor-made ball valves that matches the need of various operations,in different countries. Importantly, the application of ball valves in the oil and gas industry includes:

- Control in pipelines to transport crude oil, natural gas, and refined products.

- Refining processes where high-pressure handling and tight shut-off are critical.

Ball valves are favored for their durability and chemical resistance in chemical and petrochemical plants. They are used in:

- Managing the flow of aggressive chemicals and ensuring safe operation.

- Acting as shut-off valves in emergencies to prevent leaks and spills.

Ball valves are standard in water and wastewater treatment facilities due to their reliability and minimal maintenance requirements. Applications include:

- It controls the flow of water during various treatment stages.

- Used in pipelines distributing treated water to ensure clean and safe water supply.

The sanitary design of certain ball valves makes them suitable for applications requiring strict hygiene standards. Many ball valve suppliers craft ball valves that are customized for specific pharma industries and manufacturing of specific medicines in different parts of the world. Customized ball valves are featured with precise flow control and can automatically shut off when needed, ensuring safety and efficiency. They are used in:

- Pharmaceutical Manufacturing: Controlling the flow of high-purity fluids and gasses.

- Food Processing: Ensuring clean and uncontaminated processing environments.

Get the Best Ball Valves for Your Specific Needs! Enhance your operations with our reliable solutions.

Understanding Gate Valve

In this section, let us explore the definition, advantages and disadvantages, and application of gate valves:

What is a Gate Valve?

A gate valve is a device used to control the flow of liquids and gases. It works by lifting or lowering a gate (a flat or wedge-shaped barrier) to start or stop the flow. When the gate is fully raised, the valve opens, allowing fluid to pass through. The valve is closed when the gate is fully lowered, stopping the flow completely.

The common types of gate valves that are used in various industries include:

Wedge Gate Valve : Common in water supply systems and where tight shut-off is necessary.

Cryogenic Gate Valve : It is designed to handle extremely low temperatures.

Pressure Seal Gate Valve : Has a pressure seal bonnet for high-pressure applications.

Knife Gate Valve : Primarily used in the paper and pulp industry, wastewater treatment, and mining due to sharp-edged gates to cut through slurry.

Advantages and Disadvantages of Gate Valves

Gate valves are generally suitable for industries associated with water, gases, and chemicals and provide chemicals and provide numerous benefits. However every coin has two sides, similarly gate valves have few disadvantages too. Here are the advantages and disadvantages in detail:

| Advantages | Disadvantages |

|---|---|

| Provide a tight seal when fully closed. | Operate slowly, requiring more time to open or close. |

| Suitable for high-pressure and high-temperature applications. | Not ideal for throttling, can cause vibration and noise. |

| Minimal pressure drop when fully open | Require more vertical space for installation due to gate movement. |

| Durable and reliable with infrequent maintenance needs. | - |

| Can handle a wide range of fluids, including slurry and viscous fluids. | - |

Applications Where Gates Valves Excels

Potentially, gate valves are applied in almost every industry. Applications of these valves are seen in the following:

Oil and Gas Industry :Gate valves are a boon for the oil and gas industry. Their ability to handle high pressures and temperatures makes them ideal for controlling the flow of oil and gas in both upstream and downstream operations. Gate valve exporters often customize these valves to meet the specific requirements of the oil and gas sector.

- Operators use them to control the flow in pipelines, ensuring the safe transport of crude oil, natural gas, and refined products.

- They are designed to handle high pressures and temperatures, making them ideal for upstream, midstream, and downstream applications.

Gate valves help manage the flow of steam and cooling water in the power plant.

- They easily handle high-pressure and high-temperature conditions, making them suitable for boilers and turbine systems.

- Gate valves ensure efficient operation and safety in nuclear and conventional power plants.

Gate valves supplier craft, gate valves features with the ballast and firefighting systems which are essential in marine applications. Such application in marine offer benefits include:

- Ballast withstands corrosive seawater and harsh marine conditions.

- Gate valves control the flow of water in and out of ballast tanks.

- It ensures the vessel's stability and safety. In firefighting systems, they provide reliable operation during emergencies.

Excel with Our Top-Quality Gate Valves! Enhance performance and reliability today.

Comparison of Ball Valves vs. Gate Valves

The comparison will differentiate ball and gate valves across several key factors, helping you understand their variance and decide which is best suited for your needs.

| Factors | Ball valves | Gate valves |

|---|---|---|

| Operating mechanisms | Ball valves use a rotating ball to control flow. Easy to open and close quickly. | Gate valves use a sliding gate to control flow. Operate more slowly. |

| Flow control | Provide precise flow control. Suitable for on/off and throttling applications. | Ideal for full open or full close positions. Not recommended for throttling. |

| Pressure considerations | Handle high-pressure and high-temperature applications efficiently. | Suitable for high-pressure applications. It may have more pressure drop. |

| Installation requirements | Require less space. Easier to install in compact areas. | Installation is easy, but these valves require more vertical space due to vertical movement. |

| Cost analysis | Generally, it is more expensive initially but has low maintenance costs. | Typically less expensive upfront but may have higher maintenance costs. |

| Environmental factors | More resistant to corrosion and suitable for various environments. | It can be prone to corrosion. It needs regular maintenance in harsh conditions. |

| Durability and Longevity | Less prone to wear and tear from frequent cycling. | If appropriately maintained, it can have a longer life. However, if not, it can experience corrosion over time, especially in abrasive flow conditions. |

| Sealing capabilities | To avoid leakage, provide a tight seal even after extended use. | Sealing performance is good, fully open or closed, but can deteriorate with time. |

How do you select the correct valve for your application?

Choosing the correct valve for your application involves considering several key factors; below are the best.

Understand Your Application Requirements

Determine your requirement, whether you need a valve for on/off control, throttling, or regulating flow. By identifying your requirement, your choice of valve will be streamlined.

Understand Your Product Requirements

Make sure you choose the valve that fits your media type. Identify the type of fluid or gas the valve will control. Each media type requires specific valves: gases, liquids, oil, or chemicals. Therefore, it's crucial to identify your media accurately.

Industry Standards and Regulations

Ensure the valve meets any relevant industry standards or regulations. Ignoring the importance of industry standards and regulations can negatively impact your application in the long term.

Manufacturer and Quality

Choose a reputable gate valve manufacturer known for quality and reliability. Check for warranty options and technical support availability. Ensure the valves are manufactured by companies that adhere to rules and regulations and are registered with the government.

Which Valve Is the Best Suit For Your Application?

As you know the complete difference between a ball valve and a gate valve, it's time to choose the one that best fits your application. Before selecting any valve, purchase it from a reputed and reliable manufacturer. Keep up with the aspects discussed in this blog while purchasing a valve. It will help you make informed decisions and ensure optimal performance.

Searching for the Best Valve for Your Applications and Needs?