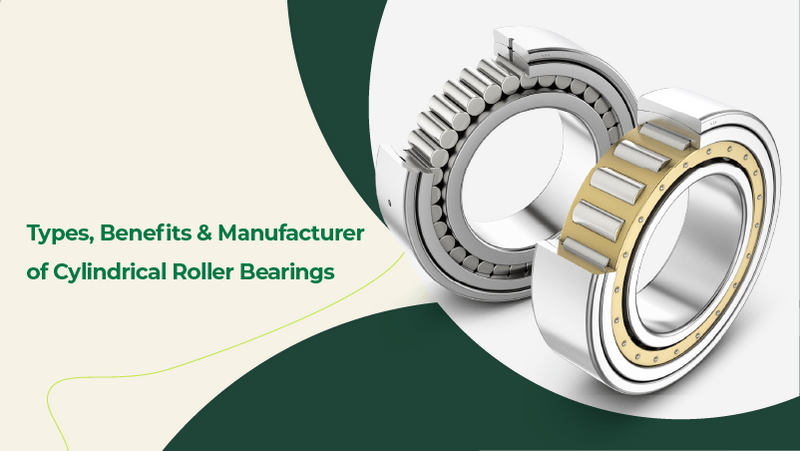

For industries battling with heavy radial loads, cylindrical roller bearings are the go-to solutions. Their compact design, exceptional load capacity, and robust performance make them an ideal choice to overcome a multitude of operations in diverse industries. The bearings act as a bridge between machinery and various mechanical components, thus helping them to reduce friction.

They are designed to withstand harsh mechanical conditions. They act as a roller element that supports heavy loads and is applicable to a range of heavy-duty equipment, making it easier for parts to travel through the cylinder. These bearings disperse loads across a larger surface area because of their linear contact surfaces with outer rings.

Let’s explore these promising bearing types and learn their role in the global market.

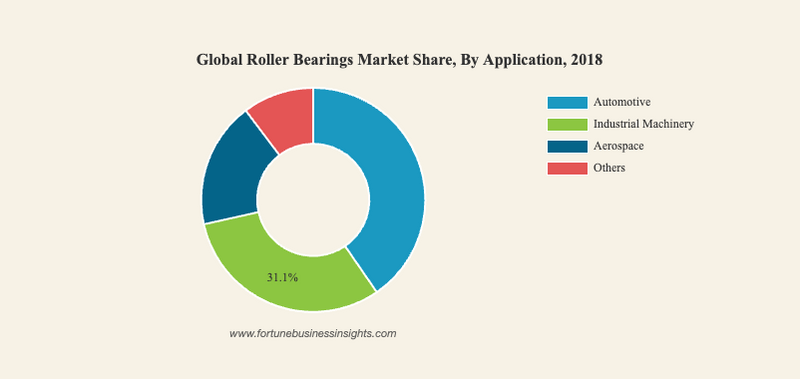

Cylindrical roller bearings global market share

Cylindrical roller bearings are considered the prominent component made by industrial bearings manufacturers for running any industrial application smoothly. According to recent statistics, the global roller bearing market was valued at $21.5 billion, with cylindrical roller bearings having the highest market share. Experts also estimated that the global roller bearing market can boom to $26.71 billion by the end of 2026 at a 3.0% CAGR.

Cylindrical roller bearings feature anti-friction capabilities that reduce friction and deliver high resistance in heavy-duty industrial applications. Thus, they help industries increase the mobility, higher load capacity, and enhanced life span of heavy-duty machines.

Here’s how the cylindrical roller bearings left their impact on the global market share

| Market share | USD 21.5 in 2018 |

|---|---|

| Expected growth | USD 26.71 in 2026 |

| Market share by applications | Automobile, agriculture, aerospace, manufacturing |

| Market share by region | Asia-pacific, Europe, Middle East, North America, South America |

| Key players | NTN bearings, SKF, NSK Ltd., IKO International, LYC Pvt. Ltd. |

| Product type | Cylindrical, tapered, and spherical |

Now that you know the booming roller bearing market share and its role in facilitating the operations of different industries, let’s understand different cylindrical roller bearing types.

- Asia Pacific- 35%

- Europe- 30%

- North America- 25%

- Others 10%

Cylindrical Roller Bearing and its types

Cylindrical roller bearings have remained popular across many industries because of their ability to handle heavy radial loads. Unlike ball bearings, which use point contact, CRBs have line contact between the rollers and races that allow them to carry much heavier loads. This makes them suitable for:

- Heavy Machinery : Examples are construction equipment like backhoes or bulldozers, mining machinery such as draglines or shovels, rolling mills for steel production, and gearboxes used in power transmission systems.

- High-Speed Rotations : When lubricated correctly and maintained accordingly, cylindrical roller bearings can cope with both high speeds and heavy loads.

- Space Constraints : Due to their high capacity-to-section height ratio, these types of bearings can be designed compactly when space is limited.

Understanding CRB Types – Choosing the Right product

While all cylindrical roller bearings excel at handling radial loads, different designs are better suited for certain applications. Here are some common types explained so you can choose the best solution for your needs:

NU (Single Row, Unflanged) : This is considered as the most basic type of cylindrical roller bearing. It consists of a single row of cylindrical rollers separated by a cage, which is housed within an inner ring and its corresponding outer ring. The unflanged design allows axial movement in one direction only. These bearings work well where there aren’t much bi-directional loadings but need higher capacity than what other designs offer due to space limitations or other considerations.

NJ (Single Row, Flanged Inner Ring) : NJ bearings look similar to NU ones because they also have just one row of rollers; however, there’s an additional feature—a flange on the inner ring that gives axial location in one direction. This could be useful when precise positioning along this axis is necessary while preventing any lateral movement away from the desired position.

NUP (Single Row, Flanged Inner and Outer Rings) : NUP bearings have flanges on both the inner and outer rings for axial location in either direction. This provides more stability and is appropriate when moderate bi-directional axial loads are expected.

N (Single Row, Filling Slot) : These bearings are basically NU bearings but with a filling slot on the outer ring. The presence of this feature enables them to accommodate a larger number of rollers thereby increasing overall load capacity compared with standard NU bearing having the same dimensions otherwise. They work best where the highest possible radial load capacity is needed within the single-row design (i.e., no need for double or multi-row configurations).

These are the four types of cylindrical roller bearings available online. Here’s how to select the correct roller bearings for your industrial application.

How to choose the correct roller bearing for your industrial application?

There’s more to it than just selecting from among these basic types of cylindrical roller bearings. The cylindrical roller bearings are available in different configurations depending on your industrial requirements. Some factors that should be taken into account include:

- Number of rows : Double or multi-row CRBs provide even higher load capacity if exceptional strength is required by an application.

- Cage material : Steel cages are common but brass or polyamide ones can be chosen for specific applications where they perform better than their counterparts made out of metal like iron alloys.

- Seals and coatings : For environments that are harsher than usual, sealed as well as coated CRBs offer additional protection against contaminants while enhancing lubrication retention properties thus ensuring longer service life under such conditions.

Cylindrical roller bearings are versatile units capable of easily taking up large radial loads. Different designs cater to various needs; therefore, knowing them will enable you to make an informed choice while purchasing or specifying a suitable CRB type for your application.

It is important to mention here that consulting with experts in this field could save time and money since they have vast experience dealing with such issues which may not be obvious during the initial stages of the selection process.

READ MORE : How to select B2B Tools and Equipment Suppliers?

Benefits of Cylindrical roller bearings

Cylindrical roller bearings (CRBs) handle heavy radial loads and provide various other benefits that can greatly improve equipment performance and operational efficiency. They are known for their ability to accommodate high speeds, shock resistance, and space-saving design, among other things, making them suitable for use in different industries. Here is an overview of these advantages.

- High Radial Load Capacity

- High Speed Capability

- Axial Displacement Accommodation

- Shock Resistance

- Simple Installation and Maintenance

- Sleek Design and Space Saving

Find the best cylindrical roller bearings for you that match all your requirements.

After understanding the types and benefits, you need to find the best cylindrical roller bearing manufacturer that supports your industrial operations.

How to choose an Ideal manufacturer of cylindrical roller bearings?

Finding the right producer for your cylindrical roller bearings (CRBs) is a must. This choice affects not only the performance of machines but also their efficiency and overall return on investment. You need to do more than just compare prices.

The following are key points to consider when choosing a perfect CRB manufacturer who can become your reliable business partner.

Expertise : Give priority to manufacturers who have worked in your industry before. Their experience means that they understand what you need in terms of application and can, therefore, suggest the most suitable CRB solution for you.

Production Capability : Look at how these producers carry out their processes during manufacturing. It would be best if they had advanced machining facilities, rigorous quality control measures, and high-quality bearing steel, which would lead to consistent production of dependable, high-performance CRBs.

Quality Control : Reliable firms follow strict quality standards such as ISO 9001 while conducting robust QC procedures aimed at ensuring uniform product quality, compliance with international specifications as well as mitigating against failures that may be caused by poor bearings.

Bearing Variants : Look for companies offering different types of CRBs in terms of sizes or tolerance classes so that you do not compromise on anything. This enables one to find exactly what they want depending on their unique applications.

Conclusion

Heavy-duty industrial applications demand uninterrupted friction for enhanced operational productivity. Installing highly durable cylindrical roller bearings is vital for your industrial units to achieve maximum industrial potential. All you need to do is select a cylindrical roller bearing designed for harsh mechanical conditions.

Select the best suitable cylindrical roller bearing that is compact and saves less space in your heavy machinery. Partner with the right cylindrical roller bearing manufacturer that follows high manufacturing standards to deliver quality products to its clients.

Want to Streamline your industrial applications with our world-class bearings?