Have you ever come across such circumstances where the success of your work depends on reliable power tools? Or are you finding ways to curate power tools, manufacturers and suppliers? Then, this blog consists of what you were searching for.

The most significant changes that have positively impacted the industry are in the efficiency of power tools. They are the most anticipated tools that have become indispensable assets, changing the way tasks are executed and majorly amplifying operational efficiency in various sectors.

From construction to manufacturers and maintenance to repair, power tools have become the driving force behind streamlined processes and more productivity.

As per reports, the global power tools market in terms of revenue was estimated to be worth USD 42.8 billion in 2023 and is expected to reach USD 65.5 billion in 2027. It will grow at a CAGR of 8.9% from 2022 to 2027.

On the other hand, businesses are increasingly moving forward to the transformative impact of power tools in their operations. They are on the search for reliable power tools, suppliers, and manufacturers. Plus, the business functions seamlessly due to quality power tools and dependability on suppliers.

A reliable supplier extends beyond providing tools. They play a major role in shaping the operational landscape of businesses. Power tools Manufacturers ensure a consistent supply of high-quality tools and become a strategic partner in enhancing business growth.

This comprehensive guide aims to navigate you to the intricate landscape of power tool procurement by providing insights, case studies and tips to empower your business.

Let us drive ahead.

Identifying specific power tools required for your industry

In the primary stage, it is necessary to understand the power tool needs, and hence, it is imperative to do a detailed analysis of industry requirements. Different industries have different demands, and the selection tailored according to specific needs optimizes efficiency.

Industry-specific applications

Recognize the basic applications in which power tools are used. For instance, precision tools like drills and grinders are essential, while for the construction sector, robust tools like jackhammers and concrete saws are used.

Workload and frequency

Check on the frequency and intensity of tool usage. In those industries where heavy-duty tools are needed, they are designed and built as per demand. On the other hand, lighter industries benefit from more versatile and adaptable options.

Precision requirements

Next is to consider the level of precision required in operation. Industries such as electronics or automotive need high-precision tools like torques, wrenches, laser cutting tools, and many others choose robustness over accuracy.

Ergonomics and user comfort

In industries for long usage, ergonomic designs and user-friendly interfaces can directly impact productivity and reduce the risk of operator fatigue or injuries.

How power tools are helpful in specific industries?

Next, factors such as type of project, frequency of tool usage, and level of precision are to be considered. Furthermore, we have listed steps to ensure that you are equipped with a clear understanding of your requirements to make an informed decision.

Quality and durability

Tools known for their quality and durability are to be prioritized. Investing in reliable brands and high-end materials enhances longevity, reduces downtime and replaces costs.

Power source

Choose the power source options that are available for the tools. It depends upon the operational needs. hence, it is good to choose between electric, pneumatic or cordless tools. Each of these tools has its set of advantages and limitations, and choosing the most suitable power source is vital.

Safety features

There are many industrial and power tools with advanced safety features. It includes protective guards, an emergency stop mechanism, and an ergonomic design to reduce the risk of accidents and injuries in the workplace.

Compatibility with existing systems

Make sure that the selected power tools smoothly integrate with existing machinery and systems. Compatibility is the key to avoiding any disruption in workflow to ensure seamless operations.

Cost considerations

As well as quality, it is also necessary to consider budget constraints. A cost-benefit analysis is required to find a balance between upfront cost and long-term value.

Remember that investing in high-quality tools pays off in terms of reliability and reduces maintenance costs over a certain time.

Supplier support and warranty

Assess the level of support offered by potential power tool manufacturers. A trusted supplier provides comprehensive customer support that includes warranty coverage and is available to replace parts.

Navigating the power tools market

The power tool market is a different and diverse landscape where an array of suppliers and manufacturers cater to various industries and their needs. Understanding the nuances of this scenario is important to make an informed decision in the procurement process.

We have curated many kinds of location-based power tools suppliers to help businesses make informed decisions.

| Aspect | Local suppliers | Global suppliers |

|---|---|---|

| Advantages | Personalized service, quicker response time. | Broader product range, scaling economy and better price. |

| Challenges | Limited product range. | Communication, shipping and logistics challenges. |

| Recommendations | For businesses who need specific local needs. | Suitable for business with diverse and global requirements. |

| Aspect | Specialized suppliers | General suppliers |

|---|---|---|

| Focus | Develops specialized types of power tools or specific to particular industries. | Wide range of tools across various categories. |

| Expertise | In-depth knowledge and tailored solutions. | Versatility in tools offered. |

| Recommendations | Ideal for industries with specific requirements. | Suitable for business with a wide range of tools needed. |

| Aspect | Online suppliers | Offline suppliers |

|---|---|---|

| Advantages | Easily browsing and purchasing and checking on customer reviews. | Hands on experience, physical inspection of products. |

| Challenges | Lack of physical inspection and many shipping delays. | Not very convenient and lacks customer reviews. |

| Recommendations | Suitable for businesses prioritizing convenience and online reviews. | Beneficial for industries that emphasize direct interaction and physical inspection. |

| Aspect | Online platforms |

|---|---|

| Advantages | Easily views customer reviews and makes comparisons. |

| Challenges | May receive biased review and lack of physical interaction. |

| Recommendations | Valuable for preliminary research and comparison. |

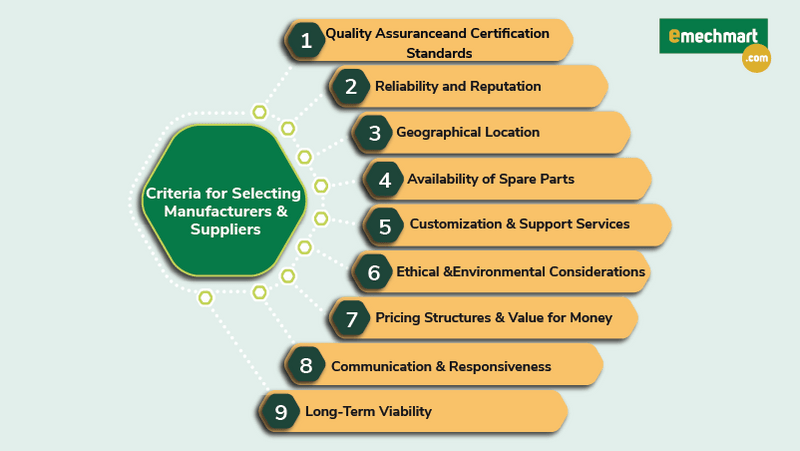

Criteria for selecting suppliers and manufacturers

Selecting the right power tool manufacturer and supplier is a critical decision that importantly impacts business operations. For making a choice, consider comprehensive criteria.

Quality assurance and certification standards

- Examine the relevant certifications by assessing the supplier's commitment to quality.

- Look if it adheres to industry standards and certifications that give a surety for the durability, safety and performance of power tools.

Reliability and reputation

- Survey the supplier's reputation in the industry by seeking referrals and customer testimonials and assessing suppliers' track records.

- A reliable supplier has a history of delivering products on time by meeting quality expectations.

Pricing structures and value for money

- Cost consideration is not the only factor that matters; there are points such as evaluating the supplier's pricing structure in relation to the quality of the product.

- Plus, the total cost of ownership is to be considered, including maintenance and replacement expenses, for a more accurate assessment of value.

Customization and support services

- The supplier's capacity to provide customized solutions that are tailored to specific needs should be analyzed.

- Moreover, a supplier who is offering personalized services adapts products to align seamlessly with operational requirements and is available to provide support services like training, maintenance and technical assistance.

Availability of spare parts

- While buying industrial tools wholesale, make sure that the supplier maintains a consistent supply of spare parts for power tools.

- It is important to minimize downtime in case any breakdown occurs. Plus, it ensures the longevity of your equipment.

Ethical and environmental considerations

- Examine the supplier's commitments related to business practices and environmental sustainability and whether they are ethical.

- Factors such as fair labour practices, environmental certification and corporate responsibility of suppliers are to be noted.

Communication and responsiveness

- The manufacturer's communication and responsiveness towards tools supplying power tools is to be smooth.

- A supplier proactive in addressing queries, providing updates and resolving issues to gain smooth business relationships.

Geographical location

- It is the most vital factor to be considered. The geographical location of the supplier is the base for a seamless business operation.

- In such a way, proximity can influence shipping costs, lead times and easy communication.

- While due to advancements in logistics, global suppliers may provide efficient services.

Long-term viability

- Evaluate the long-term goals of suppliers. Consider factors such as manufacturers' industry value, investment into R&D, and adaptability towards technological advancement.

- A supplier having a forward approach towards business growth ensures a sustainable partnership.

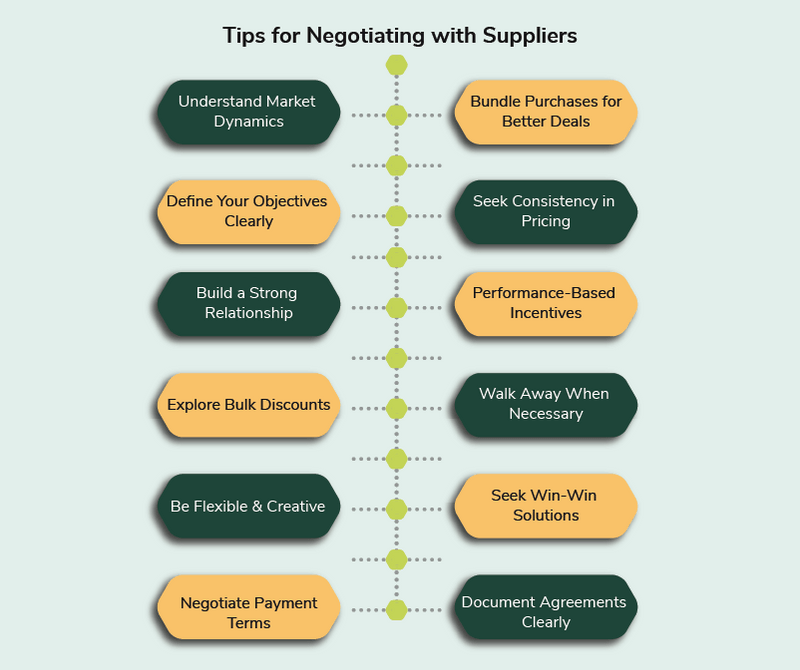

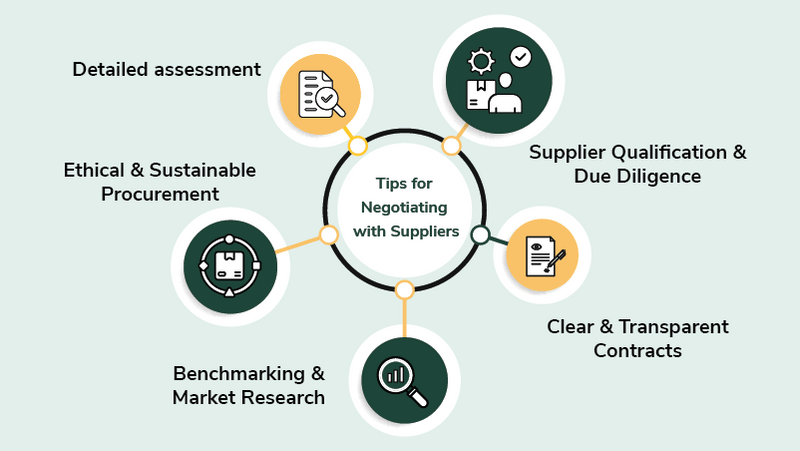

Tips for negotiating with suppliers

While buying tools directly from the manufacturer, negotiation is a crucial skill that directly impacts the terms of procurement deals and ultimately influences the success of the business. For an easy negotiations, consider the following tips:

Understand market dynamics

Conduct detailed research for current trends in the power tool and equipment market, its pricing structure, and competitors. Understanding the powerful market dynamic helps provide valuable insights to empower negotiations.

Define your objectives clearly

Define your objective about negotiations before entering into discussions. List down genuine reasons regarding price reduction, favorable payment terms, and additional service that become a well-defined objective to ensure a focused and strategic negotiation process.

Build a strong relationship

A strong and collaborative relationship with suppliers is essential. Open communication, trust, and mutual respect develop a foundation for successful negotiation and long-term partnership.

Explore bulk discounts

Suppose you are buying industrial tools wholesale; you enter into volume purchases, and hence, the possibility of volume discounts increases. In addition, the suppliers may reduce prices or add benefits for larger orders to provide cost-savings for your business.

Be flexible and creative

Be flexible while negotiating, as all the suppliers are not welcoming towards talks. List out alternate solutions and be open to creative arrangements to benefit both parties.

A flexible culture fosters a cooperative atmosphere, making it easy to find mutually beneficial terms.

Negotiate payment terms

Favorable payment terms are to be negotiated to align cash flow and financial capabilities. Enhanced payment terms or early payment discounts are to be arranged for optimizing financial arrangements.

Bundle purchases for better deals

Purchases should be combined while negotiating. If multiple products or service requests are matched into a single negotiation, it results in favorable terms, as suppliers usually favor consolidated business.

Seek Consistency in Pricing

Target consistent pricing methods to avoid fluctuation that may directly impact the budget. Discuss fixed or locked pricing for a specific period to gain stability during the procurement process.

Performance-based incentives

Launch performance-based incentives to motivate suppliers that excite them. Incentives that are bound to quality, delivery timelines, and other key performance indicators drive much improvement.

Walk away when necessary

When the negotiation does not matter to the supplier, even after giving genuine reasons, prepare to walk away. Show willingness to explore more options to reconsider the deal even after some time, for encouraging suppliers to make concessions.

Seek win-win solutions

Find win-win solutions where both parties benefit. Indulging in negotiations creates a positive environment and contributes to building a long-term and mutually beneficial partnership.

Document agreements clearly

Ensure that all the final negotiated terms are documented clearly in written contracts. Outline terms, conditions, and expectations to avoid any misunderstanding and establish a base for accountability.

Innovations in power tools

| Innovation | Overview | Innovation impact |

|---|---|---|

| Ergonomic Designs | The manufacturer relies much on ergonomic designs for enhancing user comfort and lessening operator fatigue. | The ergonomic design handles, adjustable grips and reduced vibration contributes to a more user-friendly experience to improve productivity. |

| Smart and Connected Tools | The power tools are advanced into intelligent devices with smart technological features and connectivity. | Remote diagnostics, performance tracking and adjustment of tool settings by mobile apps increase precision, efficiency and real-time tracking. |

| Brushless Motors | Mediocre brushed motors are changed with brushless technology to increase efficiency and lifespan. | Increased power, longer runtime and durability contributes to desirability of tools equipped with brushless motor. |

| Lithium-Ion Battery Advancements | The lithium-ion battery technology into electrical tools and equipments extends runtime and lifespan of cordless tools. | Longer battery life, fast charging time and increase energy mode enhances mobility and decreases downtime for cordless power tools. |

| Advanced Materials and Construction | Improvements into lightweight and durable power tools enhances tools portability and purchase. | The tools built from advanced material are more resilient in extreme working conditions, to provide longevity without sacrificing performance. |

| Precision and Laser Guidance | Precise technologies are integrated into power tools like laser guidance systems for accurate operations. | Laser-guided tools ensures precise work, reduces errors and rework, specially in industries where accuracy is critical. |

| Dust Extraction Systems | Dust extraction systems into power tools minimizes airborne particles that address workplace and safety concerns. | It improves air quality and decreases heath risks for operators in industries where dust is generated by using tools. |

| Noise Reduction Technologies | These technology mitigates high decibel levels generated by power tools during operations. | Reduction into noise levels creates a safer and comfortable working atmosphere and address to concerns regarding occupational noise exposure. |

Best practices in procuring manufacturers and suppliers

Efficient procurement practices are pivotal in ensuring a seamless and cost-effective acquisition of power tools for your business. Detailed below are best practices that companies can implement to optimize their procurement processes:

Detailed assessment

Start with a detailed assessment of power tool needs. Consider specific requirements of industry and operations.

Example: Engage with key stakeholders to gather input, analyze historical usage patterns, and check on the areas of improvement.

Supplier qualification and due diligence

Before engaging with power tools manufacturers and suppliers, it is essential to conduct a thorough qualification process to examine their reliability, reputation, and ability to meet the requirements.

Example: Check the references, review past performance, and verify certification. A reliable supplier enhances the likelihood of a successful and lasting partnership.

Clear and transparent contracts

Define the terms and conditions in written contracts to avoid any misunderstandings and disputes during the procurement process.

Example: Take advice from legal and procurement experts to draft comprehensive contracts to outline pricing, delivery schedules, quality standards, and relevant terms. Transparency in contracts is essential to build trust.

Benchmarking and market research

Continuously check on the changes in prices and practices going on in the industry. Plus, conduct market research to stay informed about the latest trends.

Example: Regularly review and update understanding of market dynamics to ensure that the procurement process remains competitive.

Ethical and sustainable procurement

Integrate ethical and sustainable considerations into the procurement process to align with corporate values and industry standards.

Example: Collaborate with suppliers who are on the same page regarding sustainability and contribute towards a positive brand image.

Tricks for long-term partnership with power tools suppliers and manufacturers

Reliable power tools manufacturers and exporters are found on the go, but establishing and maintaining long-term partnerships with suppliers is crucial for the continuous success of the business.

The following detailed strategy delves into key practices to foster enduring relationships with manufacturers:

Shared values and goals

Collaborate with suppliers who share the same values and goals to create a foundation for mutually beneficial partnerships. Communicate clearly about business values and objectives and seek suppliers whose value aligns.

Open and transparent communication

Built an environment of open and transparent communication to foster trust and collaboration with suppliers. Regularly communicate with their views, expectations, changes in any requirements, and performance feedback.

On the other hand, address the challenges frequently and maintain a proactive dialogue to ensure both parties are informed and engaged.

Joint-cost reduction efforts

Work collaboratively with suppliers to analyze cost-reduction opportunities and implement joint initiatives to benefit both parties. Regularly engage in cost-reduction discussions, exploring ways to enhance operational efficiency, optimize processes, and reduce overall procurement costs.

Long-term agreements and contracts

Create a long-term agreement and contract to provide stability and predictability to both the business and the supplier.

Plus, negotiate contracts with extended terms that allow both parties to plan the future with confidence. Outline roles, responsibilities, and expectations to mitigate uncertainties.

Flexible payment method

Ask for a flexible payment method in case of any financial strain that contributes to a positive and supportive partnership. Establish payment terms to accommodate the cash flow needs of suppliers.

A flexible payment environment speaks to commitment toward success and fosters goodwill.

Conflict resolution mechanism

Develop a crystal clear conflict resolution mechanism to address disputes or challenges that may arise during the partnership. In addition, outline steps for conflict resolution in contracts to ensure both parties have a structured and fair process to address any issues immediately. Rapid solutions to conflicts prevent damaging the relationship.

Conclusion

The complete guide to understanding power tools suppliers and manufacturers serves as a comprehensive overview for businesses seeking to enhance operational capabilities.

From understanding specific needs to navigating the market, selecting trustworthy partners, and staying ahead in technological advancement and innovations, this guide is a complete approach for power tool manufacturers' and suppliers' procurements.

If the business applies the insights gained, they can empower themselves to make an informed decision to contribute to sustained success in industrial tools and equipment industries.

Ready to Place a Bulk Power Tools Order? Connect with Top Suppliers and Manufacturers for Your Business!